Several various types of pipes are used in plumbing. These pipes are used for a range of purposes, including transferring water to fixtures such as your kitchen sink faucet and transporting waste to the sewage system in your house. Since the beginning of human history, these drainage and distribution systems have been used. Clay pipes were used to transport water from the water supply to private homes and public structures in ancient Greece. Most residential plumbing uses polyvinyl chloride, or PVC, pipes.

This specific pipe is very affordable, but it also comes with several different fittings and diameters that may be selected from. In addition to this, it is a fantastic choice for most applications that involve either warm or cold water. Both types of water may be used. Copper, galvanized steel, cast iron, terra cotta, other earthenware, and other metals like terra cotta and terra cotta all became increasingly often used as the early decades of the 20th century advanced.

As time went on, our understanding of the effects of lead poisoning increased, which allowed for significant advancement. Customers have access to a vast selection of pipes optimized for a certain use and may be purchased accordingly in today’s market.

10 Types of Pipes Used in Plumbing

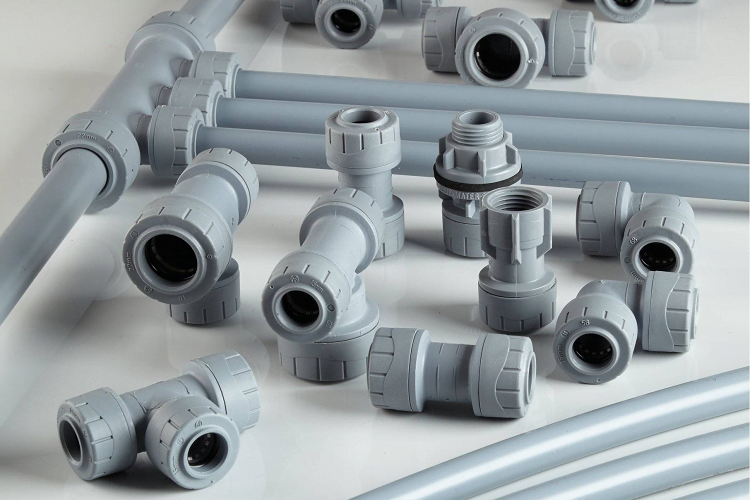

This list encompasses different types of plumbing pipes, including PVC, PEX, ABS, copper, galvanized steel, and cast iron. Examining the details that are presented in this article can educate you more.

1. PVC Pipes

Plastic is the component that makes up PVC pipe as its primary material. For water supply, drainage, and garbage disposal in residential construction, plumbing pipes composed of polyvinyl chloride, sometimes known as PVC, are typically utilized. These pipes have a reduced total cost compared to the cost of various other pipes that are often used in plumbing.

Plastic plumbing pipes are not hard to get since they are manufactured by many different companies in various geographical places all over the world. PVC pipes have great flexibility and are very durable since there is no metal or rust within the plastic piping. It allows the pipes to survive for a very long time.

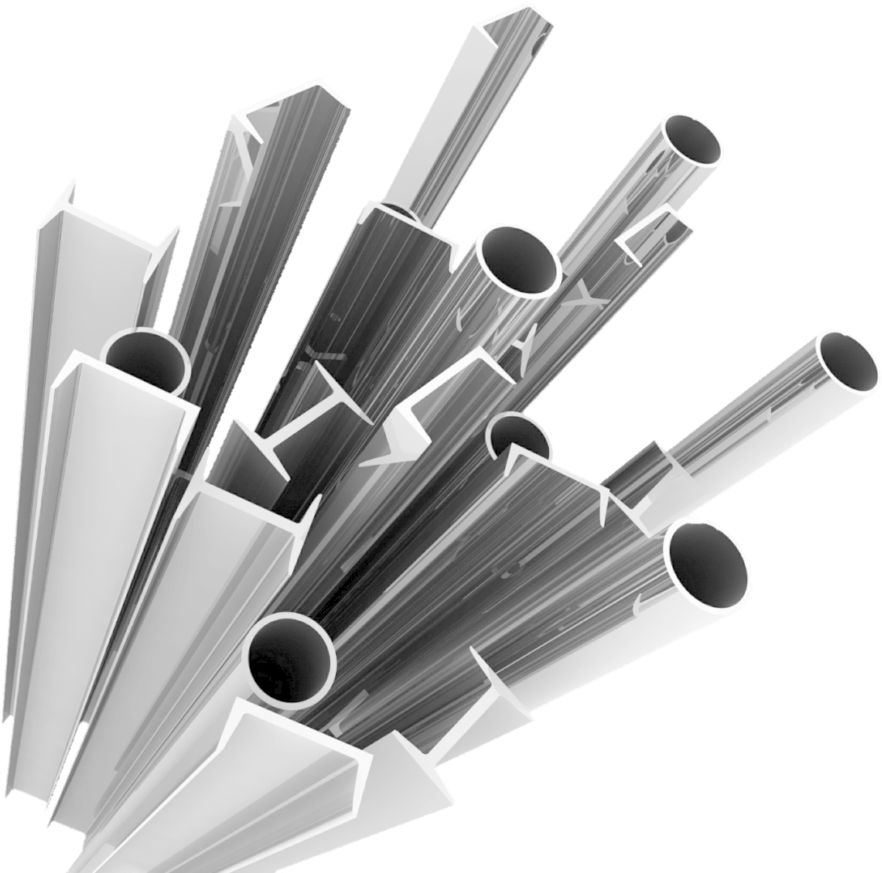

2. Pipes Made of Stainless Steel

A pipe made of copper is less expensive than a Pipe made of stainless steel, yet the cost difference is not negligible. Great prices indicate high quality. Corrosion resistant, durable stainless steel pipes. Because of their ability to withstand the detrimental effects of this process, pipes made of stainless steel are the preferable alternative in regions prone to corrosion, such as coastal cities.

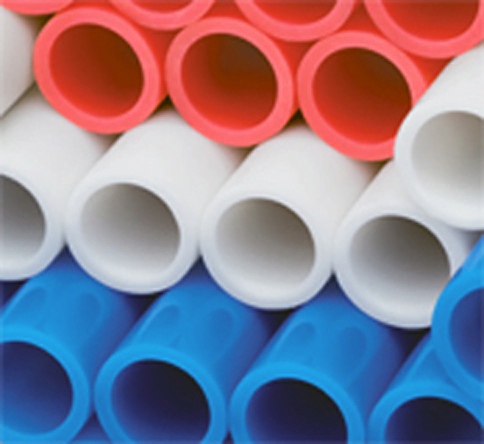

3. PEX Pipes

Cutting-edge manufacturing processes are used in creating PEX plumbing pipes, also known as cross-linked polyethylene plumbing PEX pipe is often used for the plumbing systems found in homes. PEX plumbing systems need a lower water pressure to transport liquid over a larger distance, making them an excellent choice for domestic settings.

In addition, the use of this sort of plumbing pipe may help prevent issues that arise as a result of the pipe freezing during the winter. In addition to being resistant to corrosion, it enables a substantial volume of water to pass through it without being damaged. In contrast to plumbing pipes made of metal, the flexible PEX plumbing system is simple to acquire and is also cost-effective and often comes with a warranty from the manufacturer that is good for five years.

4. Polybutylene Pipes

In the period beginning in the late 1970s and continuing into the middle of the 1990s, polybutylene pipes, sometimes known as PB pipes for short, were an alternative that was frequently used in the plumbing industry. At least one kind of polybutylene plumbing was installed in as many as 10 million homes. Polybutylene is a kind of plastic resin that was thought to be a forward-thinking chemical that would function well in the substitution of copper.

This belief was based on the fact that polybutylene had similar properties to copper. These grey plastic pipes were easy to work within a wide range of contexts and reasonably priced. However, after it was revealed that PB pipes had a high tendency for leaking at the joints where they were linked, their usage was discontinued, and they were no longer available for purchase.

5. Copper Pipes

Improving the water flow through a system may be accomplished by using a pipe composed of coated rigid copper. Your home’s plumbing system will use less energy to heat or cool the water due to the metal’s superior surface for natural convection and its capacity to reduce friction. Long-term cost savings result. A copper pipe is considered one of the most durable materials available for use in plumbing. In addition to having excellent heat conductivity, they also have high strength and a low corrosion rate.

6. Pipes Made of Black Iron

It is essential to emphasize that even though this kind of Pipe is noteworthy, it is not intended for use in plumbing applications and should not be handled as if it were built for such work. Black iron pipes were formerly a common choice for water supply piping, but nowadays, they are exclusively used for transporting natural gas or propane.

Black iron pipes were once a common alternative for water supply piping. Black iron pipes were once a common choice for water supply piping. There was a time when black iron pipes were often used for piping water delivery systems. Black iron is a common material that is used for the building of fire sprinkler systems. It is because black iron is especially effective at withstanding extremely high temperatures.

7. ABS Pipes

A pipe made of acrylonitrile butadiene styrene, more often referred to as ABS pipe, is a multifunctional and cost-effective material for the home, usually used as a drain and vent line. Its more common name is “ABS pipe.” If there is a need to establish new plumbing systems or update older ones, ABS pipe, which is quite similar to PVC pipe, is a fantastic decision that may be made. This item’s quality will be preserved for a longer amount of time because its design emphasises durability over that of materials that are more traditionally used. In fact, without incurring any damage whatsoever, these pipes can resist temperatures of up to a maximum of 1,800 degrees Fahrenheit.

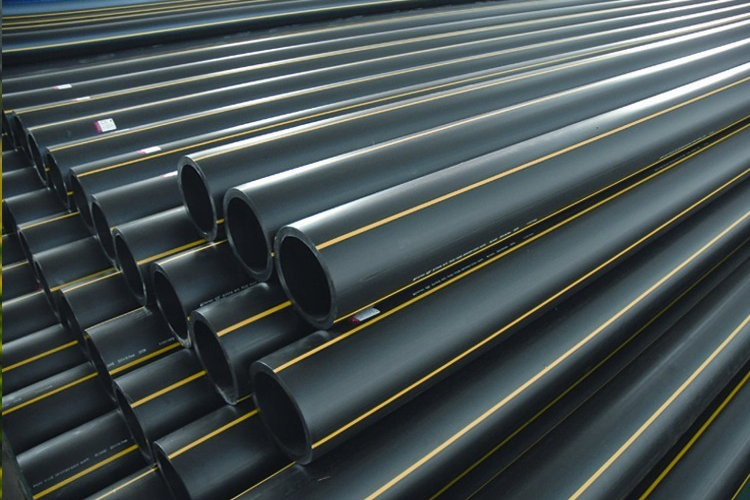

8. High-Density Polybutylene (HDPB) Pipes

When laying underground service lines, one of the most common and well-liked solutions is using pipes constructed of high-density polybutylene, which is more often known as HDPE pipes. Despite this, HDPE pipes may be used for various applications within the plumbing industry. HDPE has natural corrosion resistance and may persist for a long time.

According to the criteria of certain buildings, HDPE, and not PVC, is the kind of plastic that must be used for underground plastic lines. Because of their flexibility, HDPE pipes need a far lower number of joints than other varieties. Because of heat fusion at the joints where these pipes must have them, it is almost impossible for them to spring a leak.

9. Galvanized Steel Pipe

Steel pipes for plumbing have been used for a fairly extended period. In older homes, you’ll often find these pipes for plumbing purposes, including drainage, water supply, gas supply, and other similar tasks. The principal use for steel pipes is gas transport, even though they have a well-deserved reputation for being very durable due to their exceptional strength. Galvanized steel pipes came into existence due to an individual’s discovery in 1843 that he could coat one side of steel pipes with a combination of zinc and copper.

It would protect the pipes from rusting by generating an electro-galvanic cell between two different metals while the pipes were in use. As a result of this discovery, a galvanized steel pipe was created. However, the high lead content of this coating, which was recently linked to an increased risk of disease, is no longer utilised since it is no longer incorporated into goods. It has resulted in the high risk of illness being reduced significantly.

10. Cast Iron Pipes

Cast iron was formerly a widespread material for Pipe in drainage systems, notably in the early half of the twentieth century. Cast iron was particularly popular in the United Kingdom. Many people may still use it in their homes today. The United States of America served as a paradigmatic illustration of this pattern of behaviour. The longevity, strength, and weight of cast iron are its most remarkable characteristics.

Cast iron is not only fireproof but also absorbs sound, making it an excellent soundproofing material. However, despite the advantages of strength and durability, one important negative of cast iron is that it is prone to rusting over time. This drawback cannot be overlooked despite the benefits of strength and durability. Cast iron has a substantial disadvantage in this regard. Plastic piping, such as PVC, may be put in residential properties supplied with cast iron piping. It is done to replace a section of the cast iron pipe that has been entirely corroded by rust. There is a wide range of sizes available for pipes constructed of cast iron, with a four-inch diameter being the most common size for the lowest diameter.

Conclusion

We must have a comprehensive knowledge of the many different types of plumbing pipes and their functions. Because of it, we will be able to exercise control over the plumbing system installed in our house. Many different types of plumbing pipes are available, including PVC pipe, PEX pipe, rigid copper pipe, ABS pipe, cast iron pipe, galvanised steel pipe, and others.